Happy new year to all.

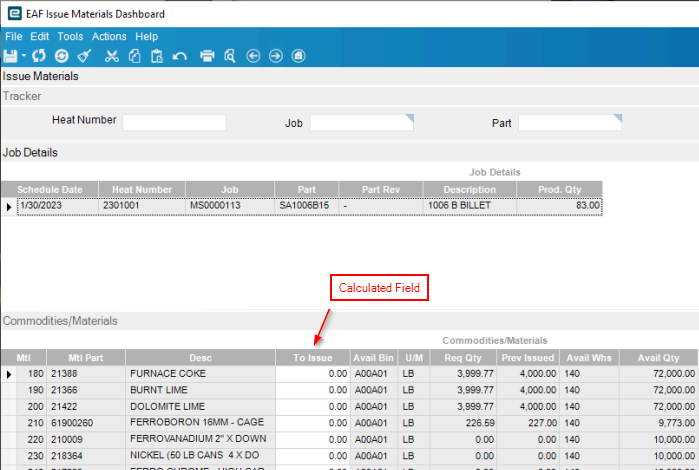

I have created an updateable stock count dashboard (we don’t use the standard Epicor stock counting process as it is too cumbersome) which gives part number, warehouse, bin, on hand qty, etc. and allows the user to record the actual quantity and thus returns any stock discrepancy. My boss would like me to take this one stage further if at all possible, and have the discrepancies post as inventory quantity adjustments from the dashboard, instead of having to do them manually.

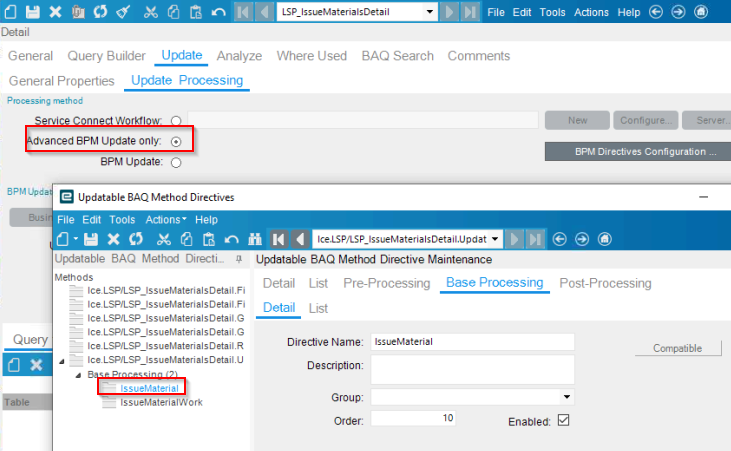

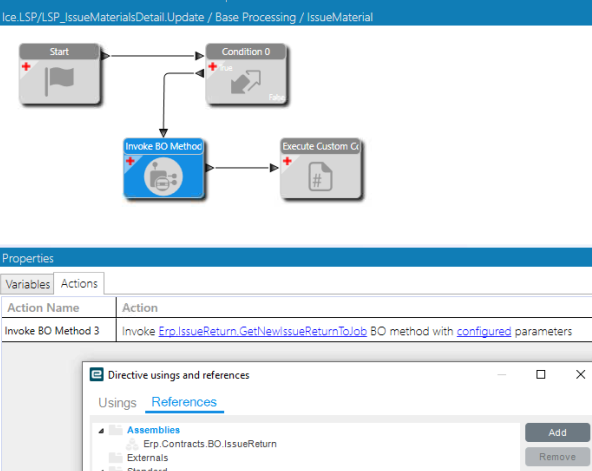

I think this should be possible using the InventoryQtyAdj adapter, and I have been experimenting with it. I have been able to get the code to call the appropriate InventoryQtyAdj business methods, but so far I have been unsuccessful in getting the info from the dashboard into the ttInventoryQtyAdj record. I get an exception message saying “ttInventoryQtyAdj record not found” every time.

Has anyone successfully achieved this, and be kind enough to share tips and/or code?

ERP 10.2.700

Best answer by pgoodhew

View original