Happy Friday All,

I am interested to hear what you have all done with MES via customization. What has worked well with the shop floor teams, what types of things do your teams wish it did better.

Thanks in advance.

Happy Friday All,

I am interested to hear what you have all done with MES via customization. What has worked well with the shop floor teams, what types of things do your teams wish it did better.

Thanks in advance.

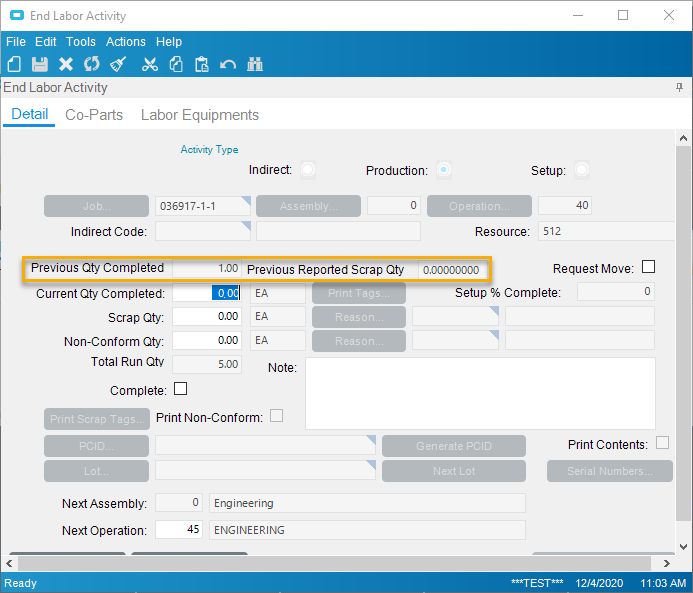

Just received a request to add the production quantity and completed quantity to the MES End Activity screen. We create jobs with a production quantity of X, but our scheduling team will request the manufacturing team only complete Y of X. This leaves jobs open within Epicor for weeks or months. Now the scheduling team wants the manufacturing team to know how many units have been completed at each operation step when performing the End Activity process. I’ll have to create a FKV on the End Activity screen to obtain this data from the JobOper table.

Also, we tested the Non-Conformance Quantity field on End Activity, and it passes the items to Incoming Inspection. Once the disposition from Incoming inspection of Pass, the non-conformance number is removed from the S/N table. Would like this data to be retained on the S/N table, for analysis by our Quality team at a later time.

We’ve done a handful of customization to MES over the years. Here are a few:

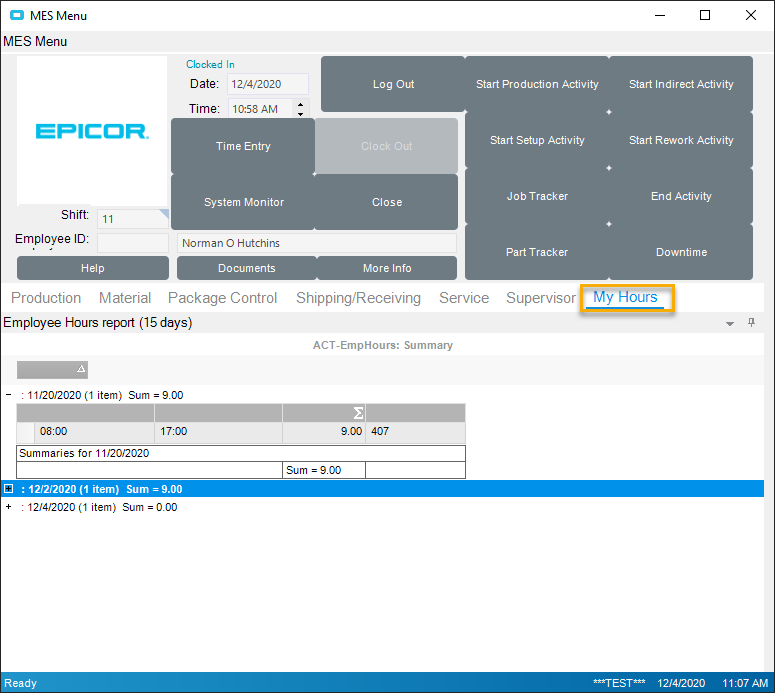

My Hours Tab - a tab displaying the current employee's last 14 days of clock-ins and outs.

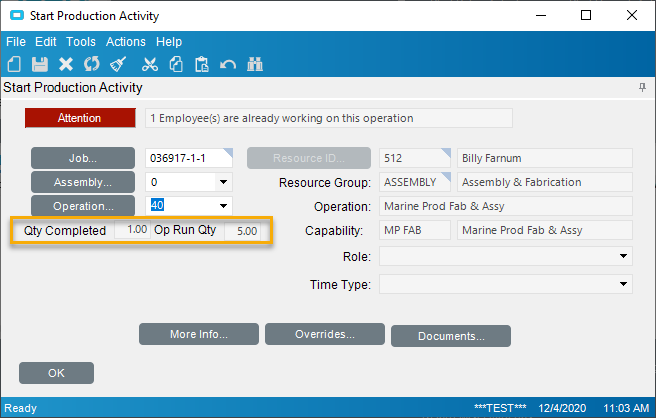

Display Previous Quantity Completed and Total Run Qty on Start Production and End Activiity. As

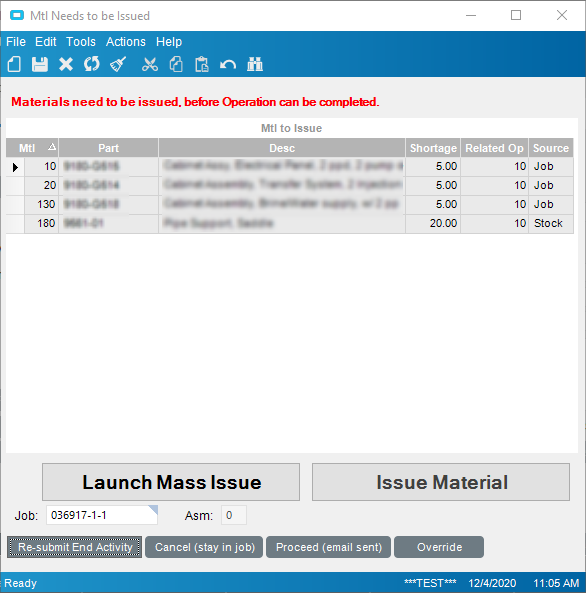

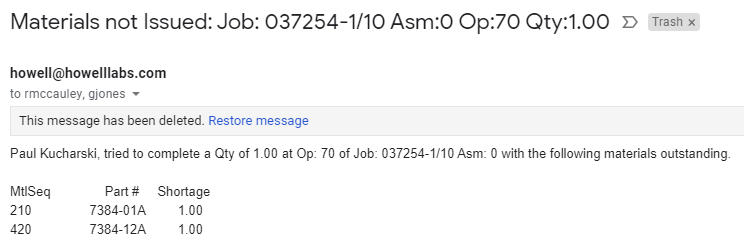

Stop Operations being marked as complete if related materials have not been issued.

We require the employee using parts to pull them and issue them in Epicor. One way to enforce this was to create a warning window; listing the outstanding mtl when an employee attempts to complete a qty on an operation.

If they get this message, they have a few choices:

Launch Issue Material with job number prepopulated to resolve the outstanding mtl issues.

Re-submit End Activity to see if the mtl issues have been addressed.

Cancel which cancels the transaction and leaves them in the job.

Hope this was useful,

-- Norman Hutchins

One of the complaints we received was having to scan three fields to log in to an operation. We modified the traveler to use a single barcode with a % character between the field data elements. We then created a program for the wand to send a tab and a short pause at the % character, Single barcode to scan and fill all three fields.

Works well and makes the process quicker and less error prone for the shop floor group. We used the Motorola/Symbol LS2208 wand for the programmability.

The 2 main areas of customization we have used are simple data validation BPM’s and adding buttons to access some BAQ reports and dashboards

MES doesn’t allow

That is unless you have AMM. - this makes MES not useful for the shops that are small and don’t need AMM.

I have had to answer this question to many users why it isn’t possible.

Why penalize a small company on some basic functionality needed on the shop floor?

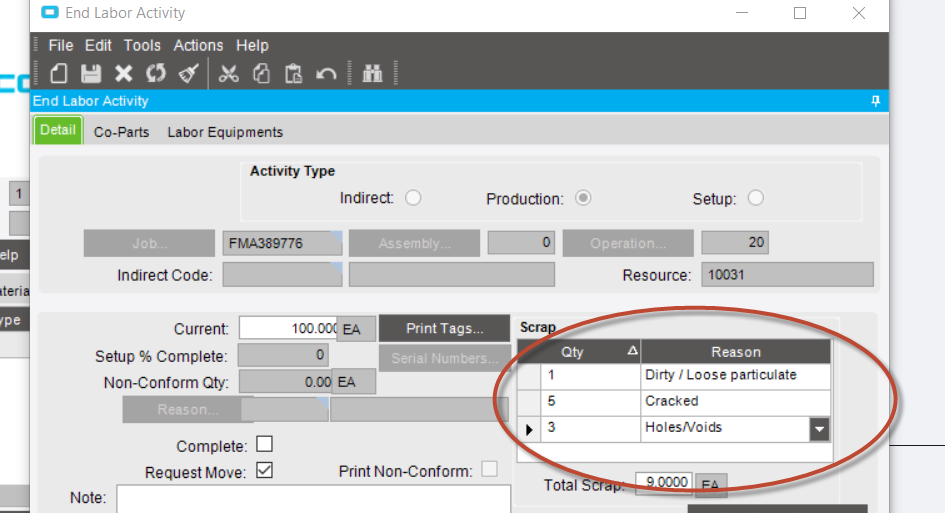

We’ve done several customization to MES mostly minor to add a tracker or otherwise change the use of a button or hide one. The most significant one which was very necessary for us was to allow the entry of multiple scrap reason codes:

Enter your username or e-mail address. We'll send you an e-mail with instructions to reset your password.